Paper-based products quickly come to mind when thinking about recycling

Few in the United States are unfamiliar with placing used newspapers, copy paper or corrugated packaging into those ubiquitous blue bins. In fact, paper recycling is deeply rooted in human history — people have been doing it for hundreds of years.

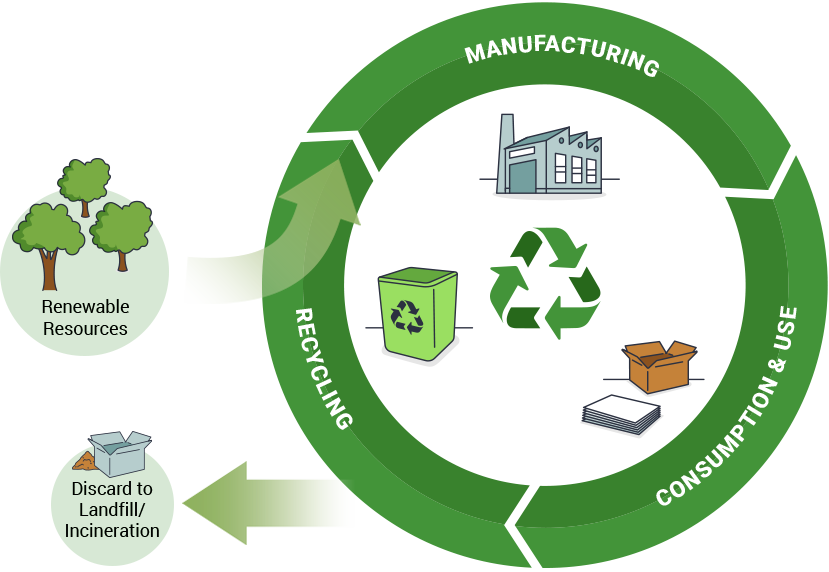

Since the 1970s, recycling methods and culture have advanced to the point that, by 2021, as much as 92% of corrugated packaging used in the U.S. was recovered for recycling.1 But traditional notions of recycling are still rooted in the “take-make-waste” model centered around “doing less bad.”

The IP Way Forward goes beyond just doing the right things — it’s about creating value for all stakeholders for generations to come. It’s about our dissatisfaction with “doing less bad” and our determination to “do more good.”

That’s why International Paper embraces the concept of the circular economy. This means that we are always looking to evolve the design of our products so that they can enjoy multiple lives through repeated cycles of reuse and recycling. We want to eliminate the very word “waste” from our vocabulary — everything we use to manufacture our products has the potential to be viewed as a renewable resource. By creating renewable solutions, we’re accelerating the transition to a low-carbon economy.

The Circular Nature of Paper Products

Circular Product Life Cycle

Linear Product Life Cycle

At International Paper, our core products are made with naturally renewable fiber: pulp. But contrary to popular belief, paper is not infinitely recyclable — the average number of times your printer paper can be recycled, for example, is about seven times.2 Paper is made up of long fibers, which shorten each time they are recycled until they no longer support the function of the product. This means that there will always be a need to introduce new pulp into the papermaking process in addition to maximizing recovery and use of recycled fibers.

To create the most sustainable business model possible, International Paper looks beyond basic recycling to evaluate our entire value chain. This means we start by championing responsible forestry, put residual materials to good use in the manufacturing process and recover and reuse fiber. To see how we’re continuing to improve our positive impact through our products, see our 2030 goal for Renewable Solutions.

Through a comprehensive approach of improving the circularity of our products and processes while being good stewards of natural resources, we ensure a steady and reliable supply of pulp for boxes, copy paper, tissues, and other products which delight our customers.

In other words: when forests thrive, so do we.

Going Above And Beyond

What happens at a paper product’s traditional “end-of-use” — whether a customer places it in the recycle or rubbish bin — will never be fully within our control. However, International Paper continues to work to increase recycling rates and encourage more recovery in the residential sector. Given our global reach and the growth of online shopping and e-commerce, we see abundant opportunities to make an even greater impact. To this end, International Paper is involved in projects with the American Forest & Paper Association and Fibre Box Association.

Globally, International Paper touches more than 7 million tons of recovered fiber annually

Going Further Together

The challenges of bringing about circular solutions in the paper industry are greater than any single company can take on alone. That’s why International Paper works across the industry, with nongovernmental organizations and governments.

We’ve aligned our efforts with the United Nations Sustainable Development Goals (SDGs), particularly SDG 12 (Responsible consumption and production), SDG 6 (Clean water and sanitation) and SDG 15 (Life on Land). By working collaboratively with others toward these goals, we can make a major impact in building a better world.

We are also are working with the World Business Council for Sustainable Development to drive the transition to a more sustainable and low-carbon economy that thrives on responsibly managed, renewable, natural resources.

These efforts don’t only help sustain the planet — they are also good for the economy. For example, the forest products industry alone supports 2.4 million jobs through the supply chain while manufacturing nearly $300 billion in products annually.4

International Paper Recycling leads in the recovery and reuse of fiber after industrial and consumer use.

95% of IP products are recyclable, reusable, or compostable

Our Commitment To The United Nations Sustainable Development Goals (SDGs)

Our Global Citizenship strategy aligns with the SDGs, demonstrating how we’re doing our part to achieve a better and more sustainable future for all. We are focusing on these goals to improve our products’ circular life cycle:

Rethinking Waste

In nature, there’s no such thing as “waste” — everything serves as a nutrient for something else. Because manufacturing waste is a human invention, we can take steps to reduce it. Practically, this includes “designing out” waste from our products. One of our innovations, ClimaShield®, improves the recoverability and recyclability of corrugated boxes through environmentally friendly waterproofing.

At International Paper, we work to make the most of every tree and the byproducts of the manufacturing process to create value and eliminate waste. We use biomass residuals from the manufacturing process to supply nearly 75 percent of the energy used in our mills. This helps us shrink our carbon footprint by reducing our reliance on fossil fuels.

Geek-Speak Defined: "renewable biomass residuals"

We love what we do at International Paper and sometimes we tend to use industry-specific terminology that may be unfamiliar to some.

Renewable biomass residuals are waste products from bark, resins and lignin that can be used as fuel to produce energy. One such biomass residual is black liquor, which results from the chemical digestion of pulpwood into paper pulp and is burned as fuel in our mills.

We put our residuals to good work. In some cases, we use these residuals and byproducts in our manufacturing process, and sometimes we sell them to other manufacturers to use.

Here are a few examples of beneficial reuse:

Ash generated from the combustion of tree bark in our boilers has agricultural value. Because it contains micro-nutrients, farmers can use the ash to stabilize the pH of the soil.

Dry ash also called “fly ash”, can be used in road construction and in the manufacture of materials such as concrete blocks and bricks.

Other wood byproducts are used to make products we use every day, such as paints, fabrics, tires, lubricants, shampoo and even cosmetics.

Your Role In Advancing The Circular Economy

Consumers like you have the power to accelerate the transition from a linear to a circular economy. Continue to purchase products made from renewable materials that include recycled content, and remember to recycle them when you are finished using them. Look for products with third-party certification like FSC® or SFI® to ensure they are made of fiber from responsibly managed forests.

Joining Forces for Circularity

International Paper is a member of the Ellen MacArthur Foundation Network, the world’s leading circular economy network. This membership enables us to advance our contributions to the circular, low-carbon economy, building on our work to evolve the design of our packaging and pulp products so that they can enjoy multiple lives through continuous cycles of recovery and reuse.

Sustainability and circularity are not a destination, but an ongoing journey. International Paper is always looking for ways to “do more good” in our operations, supply chains and products. We are proud of the work we’ve done and are doing, but we can always do more. This growth mindset sparks opportunities for innovation that allow us to develop new and improved products that both drive the circular economy forward and delight our customers. To see how we’re accelerating the transition to a low-carbon economy through innovative fiber-based products, see our Vision 2030 commitment.

Additional Resources

Downloads, fact sheets, reports and more.

FAQs

Answers to frequently asked questions about forestry, paper, packaging and pulp

Does Using Paper Products Kill Trees?

How responsibly produced paper products actually keep forests forested

Learn MoreAre Recycled Paper Products Always Better for the Planet?

Recycling is only part of the sustainability equation

Learn More